#plastic molding low volume

Explore tagged Tumblr posts

Text

Injection Molding for Low-Volume Production: Cost-Effective Solutions for Small-Scale Manufacturing

Injection molding, a highly efficient and versatile manufacturing process, is often associated with high-volume production. However, it also offers valuable benefits and cost-effective solutions for low-volume production, catering to small-scale manufacturing needs.

Low-volume injection molding refers to the production of a relatively small quantity of plastic parts, typically ranging from a few hundred to several thousand units. This approach is ideal for prototyping, small-batch production, or niche market applications. Despite the lower quantities involved, injection molding still provides advantages such as superior part quality, design complexity, and material options.

One of the significant advantages of low-volume injection molding is its cost-effectiveness. While tooling costs may remain similar to high-volume production, the overall per-part cost can be justified for low-volume runs due to the amortization of tooling expenses. Additionally, injection molding's high production efficiency enables faster production cycles and reduced labor costs compared to alternative manufacturing methods.

Low volume injection molding offers flexibility in design iterations, allowing for quick adjustments and improvements before finalizing the production mold. This iterative approach saves time and costs during the product development stage, leading to faster time-to-market for new products or modifications to existing ones.

Moreover, injection molding low volume ensures consistency in part quality and dimensional accuracy, thanks to the precise control offered by modern injection molding machines and techniques. This reliability is crucial for maintaining customer satisfaction and meeting industry standards.

In summary, injection molding is not solely limited to high-volume production. Low-volume injection molding provides cost-effective solutions for small-scale manufacturing, offering superior part quality, design flexibility, and shorter time-to-market. Manufacturers can confidently leverage this technique for their low-volume production needs, benefiting from the efficiency, precision, and versatility of injection molding.

#lowvolume#low volume mol#2K injection mould#low volume moulding companies#small quantity injection molding#low volume plastic parts production#low volume low cost plastic injection moulding#low volume injection molding companies#plastic molding low volume

0 notes

Note

YES PLEASE. BLOCKBUSTER ELLIE?? 90’s?? SIGN ME UP. WHERE DO I PUT MY NAME??😖😖🙏

- 🩵

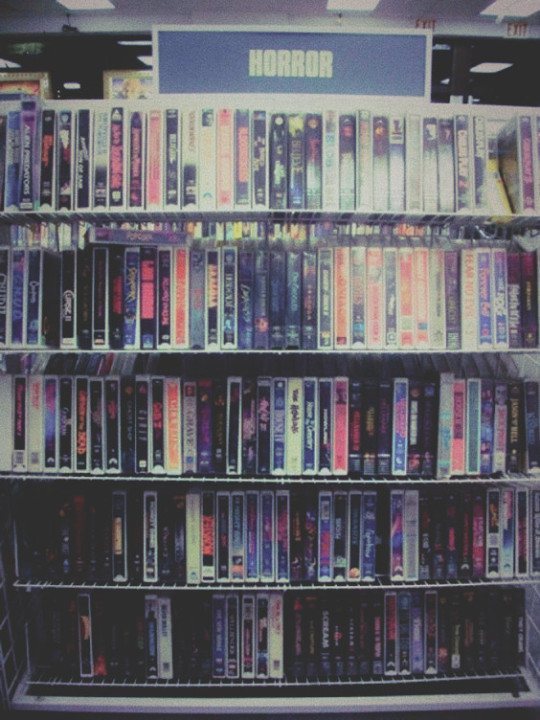

a/n + cw; OMGG AN EMOJI ANON i haven't seen you guys in a hot minute, but YESSS BLOCKBUSTER ELLIE!! specifically x customer reader. it's a cute duo! and let me relay why from my very scrambled 3 am jot-down. was going to make this a blurb, but it better translates through something more structured. ++ SFW! kinda mean!reader tbh (but ellie likes that), very fluffy you might squeet, quickly written, awkwardness, ellie being a nerd. [first pic from amoaeIIie on pinterest]

Imagine Ellie, in her blockbuster getup, leaning her butt into the edge of the register counter, jamming to whatever is playing on her hand-me-down walkman; earsbuds in, eyes downcast, head bopping slowing - soundly unaware of you awaiting service on your over-due rental. "Hello?" your volume divides the soft ambiance of the store, but it isn't enough to rope Ellie's mindspace from the clouds. Calling out again, "Hell-looh?" you extend beyond the cash register and wave your hand - nothing, nada.

How the hell has this girl not gotten her ass fired yet?

After numerous roadblocks, a brazen last resort comes into play. You cut around the counter briefly to take things into your own hands (literally) because you have not the time, nor the patience, for her slacking off.

Beryl eyes drop sharply to the walkman in her pants pocket when a single earbud is spooled from her ear, assuming it fell - but to her surprise, it hung low from your finger, and a glance above that finger was your face. Risen of one brow, flat-lined of your lips; impatient.

And her entire focus blanks out when you begin to speak, curtly and satirically, "Hey, I know busting out your Dad's old walkman in public makes you feel cool and whatnot, but you're on the clock." handing the slim cord back over to a stunned girl, flushed behind the pop of her freckles. Maybe your tone of voice sent her higher into the clouds, past a coven of angels, because her lips part narrowly and remain still for a single second - save two or three. Or maybe it's 'cause you specified it as her 'Dad's' which was.. spot on.

And whatever excuse she had quickly cherry-picked for you, hesitated audibly in her throat before it split from it, "O-Oh, right, shit sorry - was about to end my shift n' thought the store was empty. My bad." scrambling to stuff the other earplug in her pocket and avert all attention to you. Very eagerly.

"Looks like you've got a late fee on this one.." her pitch pummeled deeper, and coarser as she concentrates on the clunky screen she hunches slightly to use. Scrunching the freckles of her face together, hogging the blue-lit screen. Poor girl probably forgot her glasses at home. "Annnd are you looking to rent the sequel?" she peeks her auburn head from the screen and holds up the cased movie, tracing her index over the plastic cleft, tapping twice. "To this - it has a second part."

There's no denying it: she is cute - and guilt rolls your guts around for being so snippy and sullen to her earlier. But based on her demeanor growing enthused the second she saw what movie you had in hand - she doesn't seem to care a hoot.

"Out of stock," replied you, indifferent-sounding - and strking; crossed arms, bent knee, stiffly-standing. Comparable to a millpond. "Guess I won't be the only person with late fees." you take a breath to jest, shaking loose strands of hair from your eyes.

"Haha," you're no world-class comedian; that joke wasn't all that funny, but the need to hurl any affirming noise at you, was necessary. Relenting to reflex. What can she say? Love at first sight! "Yeah, that seems like the agenda these days," Ellie sighs out, molding the plump of her lip under her teeth and reshapes it into a dorky smirk. Isn't she just a sweet chocolate-box of adorability?

"Hmm, bummer."

That hum and word trips into her ears, knocking some brain-cog, and an idea limns her features; they glow wide. "Actually - um, I've got a copy of the sequel at my place. Technically it's my Dad's, but.." her pitch fluctuates, mindlessly thumbing the case between two fiddly hands. "Maybe you can - if you want, not pressuring you or anything - come over?" she throws a pointed thumb backwards, motioning a potential future. "Watch it? If you weren't planning on watching it with somebody else."

Slick trick to seeing if you're single; of course you'd watch movies with your boyfriend - or girlfriend.

"Hmmm.." you hummed longer this time, and this time it admitted the mushrooming of an almost aggravating anticipation in her belly. Like you meant to torture her with 'hmms' and nothing but 'hmms' as your answer hung high in cloudy abeyance, until, "What's the name on your tag - ah, Ellie."

"Yeah?"

"Ellie," you confirm her name twice, and speak it to enthrall her full-scale attention. Made it sound fucking sugary sweet, through a swirly whisper and a twist of your head. "If you can give me a discount, or a full wipe on that late fee, then yes. It's a date."

Light panic ensues. "Date?" she croaks and laughs it off, "I mean - pshh, guess that's one way to put it." backtracking to her hunched, elbows-on-the-counter pose.

"You put it that way."

"Yeah, I just.. didn't wanna admit that." immediately, she uncurls her spine again, relaxing her muscles to somewhat peer at you. "Sure. No more fees." Rounded eyes lost - adamant on indirectly staring at you and the space below you, because Goddess forbid a stroke of idiocy flickers through her while gawking at you.

The store runs dead-quiet in the background of your conversation, leading you to one golden question. "Your shift over after this?"

Oh damn, her cheeks are pink. "Uh-huh," bet she's oblivious to that red-hot beam nearly bursting the seams to her face, too. Nasal lines fold as a severe smile tugs, shadowed by her bent thumb poking at it. "Takin' my car?"

And that's how you pick up girls at a video store in the 90s - the Ellie Williams way.

this isn't even the full idea

#✮─── . aestra's bibliotheca#ellie williams#ellie williams x reader#ellie tlou#ellie williams fluff#⤹𓍢ִ໋aestras asks#lesbian#sapphic#ellie x reader#ellie williams x fem!reader#ellie williams x masc!reader#ellie williams fic#⋆ .🩵 anon#ellie williams concept#blockbuster!ellie#ellie williams drabble#ellie williams oneshot#the last of us fanfiction#ellie the last of us#ellie the last of us 2#the last of us 2#the last of us au#ellie williams au#ellie williams fanfiction#ellie x fem reader#ellie williams smut

772 notes

·

View notes

Text

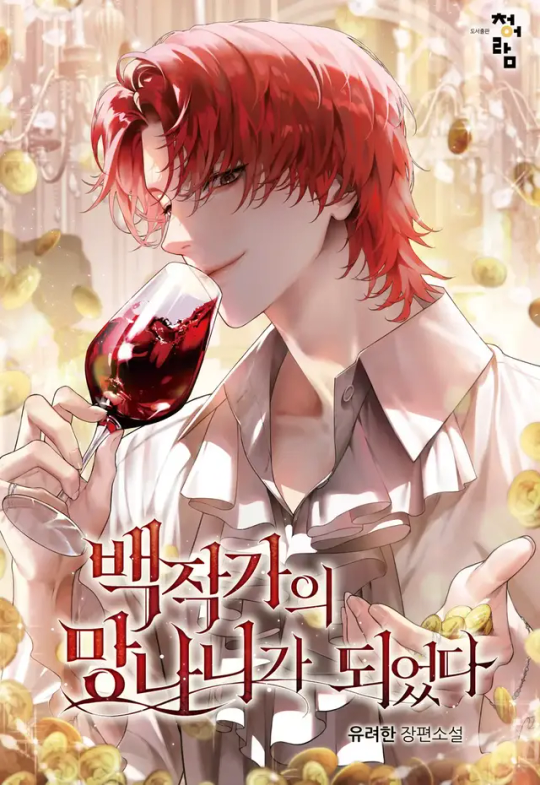

TCF Modern AU Character Checklist (Official)

RIDI, one of the Korean publishers of TCF/LCF, recently released new ebook volumes for TCF. The volume set consisted of volumes 10-18, spanning chapters 201-398 of Part 1. And RIDI added a "Character Checklist" as the exclusive bonus content for buying the volume set.

What is this character checklist about? It's just a list of things that the characters are most likely to do or prefer. But it is set in a modern AU (alternate universe) setting.

Those who want to purchase official merchandise can head over to RIDI to buy the new ebooks. You can get a 10% discount and a 5000 won coupon if you participate in the event, so the cost for the new volume set will only be 24,160 won. But be aware that this is only in the Korean language. There is no official English ebook for TCF. 🥲

The new ebooks included new novel covers. For volumes 1 - 9, they changed the ebook cover to this:

And for volumes 10-18, the new ebook cover is this:

Because the character checklist is not publicly available for free, I will only post a quick summary of it.

***

Alberu

likes to eat snacks while working

beautiful handwriting

celebrates others' birthdays grandly

frequent social media poster because of work

Beacrox

makes tteok-galbi and gives it to Cale

2nd best at making snow ducks

Ron

makes travel plans because of the kids

good at claw machines

Bud

world traveler who's good at driving any vehicle

frequent social media poster because he's an attention-seeker

Hilsman

scared of bugs

Witira

heavy drinker

troublemaker child because she couldn't control her strength

Eruhaben

good singer of old songs but only does it upon the kids' request

picky appetite

doesn't use kiosks because he's not interested in learning anything new

On

great dancer

makes travel plans

knows the most about memes

Hong

makes travel plans

likes winter because of family get-togethers

frequent social media poster because he finds it exciting

good at drawing because everyone praised their drawings

posts memes

Raon

makes travel plans

prefers to play together than go on amusement park rides

likes winter because of family get-togethers

late sleeper because he always daydreams of going on trips with his family

good at drawing because everyone praised their drawings

Choi Han

stiff dancer

secretly prefers thrills in the amusement park

good at making snow ducks

student with low grades

Deruth

believes in fortune telling stuff but is in denial over it

Cale

somehow ends up as the leader in team projects

celebrates others' birthdays secretly

best fit as the leader of a K-pop boy group

buys lots of online books to read when he achieves slacker life

heavy reader

drinks hot Americano because Ron says cold drinks is bad for him

Mary

likes spicy food

likes horror movies

good at computers because Tasha taught her

Lock

first to apologize after getting into a fight

model student with good grades

Tasha

loves to eat meat

Archie

always grumbles on trips but shuts up when Cale stares at him

Toonka

bad at using machines and gadgets

Cage

prefers eating over studying

Rosalyn

drinks iced Americano in the morning

troublemaker child because she wanted to do lots of things

Jack

likes pineapple pizza

Hannah

likes mint chocolate and eats it together with Mary

***

Some trivia:

Mint chocolate in Korea is similar to pineapple pizza that people either heavily like or dislike.

Witira being a heavy drinker is a pun related to her race as a whale tribe. Sulgorae (술고래) is a figurative expression for a heavy drinker. It’s a combination of the words 술 (alcohol) and 고래 (whale). English has a similar expression to it - drink like a fish

Making snow ducks is a trend in Korea. They use plastic tongs with a duck mold to create snow ducks. Some treat is a game where you make dozens of it fast as if printing out items in a factory, and line it up in a row.

Tteok-galbi is grilled short rib patties. Hmm, delicious~! 😋

175 notes

·

View notes

Text

I made these english muffins and they are so good 10/10 recommend

Recipe adapted from KA flour

Ingredients -8 ounces bread flour (1 1/2 cups; 225g) (I used 3/4 whole wheat bread flour + 1/4 cup AP bc that was the only bread flour I had and it was awesome) -8 ounces (1 cup; 225g) warm water, between 110°F-115°F -8 ounces (1/2 cup; 225g) leftover sourdough starter (unfed/discard, see note) -1.5 ounces non-fat dry milk powder (6 T) (I used 3/4 cup warm milk with 1 cup yogurt stirred in instead of warm water and milk powder) -1 ounce (2 tablespoons; 30g) unsalted butter, melted -1/2 ounce granulated sugar (1 tablespoon; 15g) -1 teaspoon salt -3/4 teaspoon instant yeast -extra butter for greasing ring molds Directions

In a large bowl, whisk together flour, water, sourdough starter, milk powder, butter, sugar, salt, and yeast until smooth. Cover with plastic wrap and let stand at room temperature until batter has roughly doubled in volume, about 1 hour.

Heat griddle or pan on medium heat. Grease the inside of eight 3 1/2-inch English muffin rings or round ring molds with non-stick cooking spray and place on griddle. (I used 3 at a time in my 10-inch cast iron bc I don't own a griddle) Without stirring the batter, use a 1/3 measuring cup to evenly portion it into the rings. Cover rings with a baking sheet, reduce heat to low, and cook undisturbed for 5 minutes.

Remove baking sheet. Using tongs to hold rings in place, slide a spatula underneath muffins and flip over to cook other side. Cover again, and cook 5 minutes longer.

Remove baking sheet. Using tongs, remove rings from muffins and set aside. Using a spatula, transfer muffins to a wire rack to cool for about 10 minutes. Split English muffins by hand or with a fork. If desired, toast before serving.

4 notes

·

View notes

Text

Working of Vacuum Casting and Its Multiple Uses

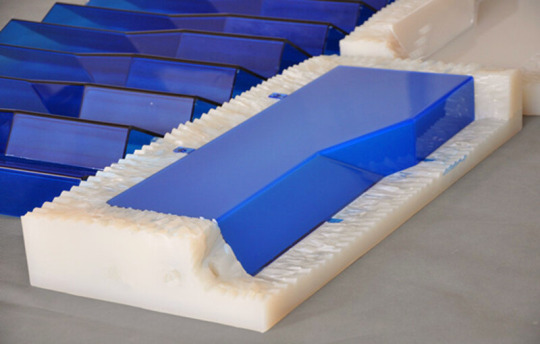

To make complicated components, a liquid substance is sucked into a silicone mold under vacuum. This method is known as vacuum casting. Rubber and plastic are examples of elastomers that are utilized as liquid materials in vacuum casting.

Since polyurethane resin, a kind of elastomer is employed as the casting medium, vacuum casting is also frequently referred to as polyurethane casting or urethane casting. When producing plastic components, vacuum casting is a more cost-effective method than injection molding because of its reduced manufacturing costs.

For batch manufacturing and other low-volume production tasks, vacuum casting is a great method of production. Vacuum casting is widely utilized in India's manufacturing of industrial electronics, FMCG, and consumer goods.

How do you work with vacuum casting?

Injection molding, in which cast material is poured into molds to create items, and vacuum casting services are very comparable processes. The kinds of molds used in injection molding and vacuum casting differ from one another.

Molds for injection molding might be formed of steel, aluminum, or other materials. Silicone molds are utilized in vacuum casting, nevertheless. This significantly lowers the mold-making cost because silicone is more affordable and has better durability.

Polyurethane is the most often utilized casting material in this procedure. The qualities of various polyurethanes vary, including good shock and temperature resistance, elasticity, flexibility, and structural stiffness. Thus, different polyurethanes may be employed depending on the kind of product being created.

Vacuum casting uses

Making complicated and sophisticated goods may be accomplished more cost-effectively and efficiently with vacuum casting as opposed to the conventional injection molding method.

Due to its efficient production process, vacuum casting finds widespread application in the fabrication of commercial items. The following are a few industries that employ vacuum casting:

Manufacturing of consumer goods

Vacuum casting is a more effective method of producing consumer goods including combs, hair brushes, makeup packaging, sunglasses, pens, and other stationery.

Industry of Food and Beverages

Vacuum casting is used to create food and beverage containers, bottles, cans, mugs, and glasses. Due to the process's great efficiency and ability to produce goods quickly, vacuum casting is widely utilized in various industries where rapid manufacture is essential.

Advanced industry

Excellent heat and shock resistance is a feature of polyurethanes. Therefore, the recommended production procedure for creating electrical device housings is vacuum casting by Vacuum Casting Manufacturer using polyurethanes.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Explore vacuum casting#Vacuum Casting Services China#Vacuum Casting Manufacturer#Vacuum Casting supplier

2 notes

·

View notes

Text

Efficient Manufacturing Solutions with Rapid Tooling for Faster Production

In today's fast-paced manufacturing world, the demand for shorter lead times, efficient production, and high-quality output is at an all-time high. Rapid tooling has emerged as a key solution to these demands, providing manufacturers with a cost-effective and efficient way to produce high-quality components. By using advanced techniques and technologies, rapid tooling bridges the gap between prototyping and full-scale production, allowing for faster and more accurate part creation.

What is Rapid Tooling?

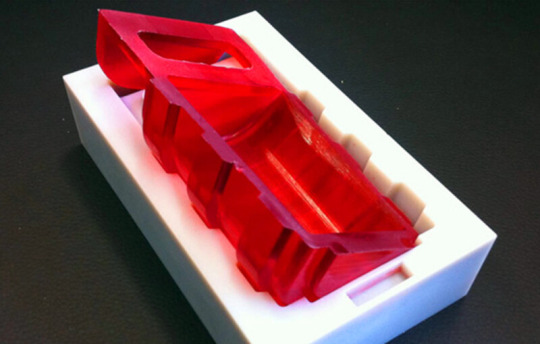

Rapid tooling, also known as bridge tooling, is a manufacturing process used to create molds, dies, or other tools quickly and affordably. This method leverages technologies like 3D printing, CNC machining, and other techniques to produce tooling with shorter lead times than traditional methods. Often used for prototype or low-volume production, rapid tooling allows companies to test and refine designs before moving into high-volume production. The ability to make adjustments on-the-fly without incurring high costs is a major advantage of rapid tooling, especially for industries that need to adapt quickly to market demands.

Key Techniques Used in Rapid Tooling

There are several techniques commonly used in rapid tooling, each offering unique advantages depending on the project requirements. Some of the most popular methods include:

3D Printing: This technique allows for the rapid creation of complex shapes and intricate details that would be difficult to achieve with traditional methods. 3D printing is commonly used in creating prototype molds and dies, providing a quick and cost-effective way to evaluate designs.

CNC Machining: CNC machining is another vital technique in rapid tooling, enabling precise and high-quality tooling at a fraction of the time. CNC machining allows for the creation of metal and plastic parts that can be used in both prototype and production molds.

Casting: In some cases, casting is used to create rapid tooling molds by pouring a liquid material into a 3D-printed or CNC-machined mold. This technique is particularly useful for producing complex parts with a high degree of accuracy and detail.

Each technique has its specific advantages, and often, manufacturers use a combination of methods to achieve optimal results for a particular project.

Benefits of Rapid Tooling

Rapid tooling offers significant benefits that contribute to faster, more efficient, and cost-effective manufacturing processes. Some of the primary benefits include:

Reduced Lead Times: Traditional tooling can take weeks or even months to produce, but with rapid tooling, manufacturers can create molds or dies within days. This reduction in lead time allows companies to speed up their production cycles and respond more quickly to market changes.

Lower Costs: Rapid tooling is generally more affordable than traditional methods, making it an ideal choice for small to medium production runs. By utilizing advanced manufacturing techniques, companies can reduce labor and material costs while still achieving high-quality results.

Flexibility: One of the standout benefits of rapid tooling is its flexibility. Manufacturers can make quick changes to designs without a significant impact on cost or time. This is especially valuable during the product development phase, where adjustments may be needed to ensure optimal performance.

Scalability: Rapid tooling allows for low to medium production runs, making it an excellent option for companies looking to test the market or produce custom parts. This scalability makes it a viable solution for various industries, from automotive to aerospace and beyond.

Applications of Rapid Tooling Across Industries

Rapid tooling has gained widespread adoption across numerous industries, thanks to its versatility and efficiency. Some common applications include:

Automotive: In the automotive industry, rapid tooling is used to produce prototype parts and molds for testing, helping engineers evaluate and refine designs quickly. This approach allows for better customization and adaptation to new trends and regulations.

Aerospace: Aerospace components often require precision and strict quality standards, making rapid tooling an ideal solution. By creating precise and durable molds, manufacturers can produce aerospace parts that meet rigorous industry specifications.

Medical: Rapid tooling is extensively used in the medical field to create custom parts and molds for medical devices. The ability to produce small quantities at a low cost and adjust designs on-the-fly is especially valuable in this industry, where customization and adaptability are crucial.

Consumer Goods: Many consumer goods manufacturers use rapid tooling to create short-run molds for customized products. The method enables quick iterations and modifications, helping companies keep up with market trends and consumer preferences.

Future Trends in Rapid Tooling

As technology continues to advance, rapid tooling is expected to evolve further, offering even more possibilities for efficient and cost-effective manufacturing. Some of the emerging trends include:

Integration of AI and Automation: The integration of artificial intelligence (AI) and automation in rapid tooling processes can lead to more precise and efficient production. AI-driven algorithms can optimize tool design and material selection, reducing waste and improving product quality.

Material Innovation: New materials are continually being developed to improve the durability and performance of rapid tooling. The introduction of high-strength polymers, composites, and even metals compatible with rapid tooling processes enables manufacturers to expand their range of applications.

Increased Adoption of Additive Manufacturing: Additive manufacturing, or 3D printing, is set to play a more significant role in rapid tooling. With advancements in 3D printing technology, manufacturers can create complex geometries and highly accurate molds, further reducing the time and cost of the tooling process.

In conclusion, rapid tooling offers a host of benefits for manufacturers seeking to improve efficiency, reduce costs, and increase flexibility. By leveraging advanced techniques and materials, this approach to tooling provides a valuable solution for industries requiring rapid and adaptable production options. With ongoing technological advancements, rapid tooling is poised to become an even more integral part of modern manufacturing.

0 notes

Text

Injection Molding Vs Urethane Casting: Key Distinctions

When it comes to creating parts and products, manufacturers often choose between different methods. Two popular methods are Injection Molding and Urethane Casting. Both techniques have unique advantages and limitations. Understanding these differences is important for making the right choice for your project. This article will explore both methods in detail.

What is Injection Molding?

Injection Molding is a manufacturing process. It involves injecting molten material into a mold. This method is commonly used for producing plastic parts. Here are some key points about Injection Molding:

It is fast and efficient.

It produces high volumes of parts.

The molds can be expensive to create.

It works best for thermoplastics.

How Injection Molding Works

The process starts with a mold. The mold is designed to the shape of the desired part. Next, the plastic pellets are heated until they melt. The molten plastic is then injected into the mold. After cooling, the mold opens, and the part is ejected.

What is Urethane Casting?

Urethane Casting is another manufacturing process. It involves pouring liquid urethane into a mold. This method is great for low-volume production. Here are some important points about Urethane Casting:

It is cost-effective for small runs.

It requires less expensive molds.

The curing time can vary.

It can produce complex shapes.

How Urethane Casting Works

For Urethane Casting, a mold is created, usually from silicone or another flexible material. The liquid urethane is mixed with a curing agent. Then, it is poured into the mold. After a set time, the urethane hardens, and the part is removed.

When to Use Injection Molding

Injection Molding is ideal for certain situations. Here are some cases when you should choose this method:

You need large quantities of parts.

You want high precision and consistency.

You are using thermoplastic materials.

You have a larger budget for mold creation.

When to Use Urethane Casting

Urethane Casting is suitable for different scenarios. Here are some examples when this method is a good choice:

You need low-volume production.

You want to save on mold costs.

You need to create complex shapes quickly.

You are working with limited resources.

Advantages of Injection Molding

Injection Molding comes with several advantages:

High production speed.

Consistent quality across large batches.

Can create intricate designs.

Strong and durable parts.

Disadvantages of Injection Molding

However, there are also some disadvantages:

High initial costs for molds.

Longer lead times for mold creation.

Not suitable for small production runs.

Advantages of Urethane Casting

Urethane Casting also has its benefits:

Lower costs for molds and materials.

Faster turnaround times.

Ideal for prototypes and small batches.

Flexible in design and application.

Disadvantages of Urethane Casting

Some downsides of Urethane Casting include:

Limited production volume compared to Injection Molding.

Parts may not be as strong as injection molded parts.

Curing time can vary, affecting production speed.

Frequently Asked Questions

What Is Injection Molding?

Injection molding is a manufacturing process that creates parts by injecting molten material into a mold.

What Is Urethane Casting?

Urethane casting involves pouring liquid polyurethane into a mold, allowing it to cure and form a solid part.

How Do Injection Molding And Urethane Casting Differ?

Injection molding is suited for high-volume production, while urethane casting is ideal for low-volume and prototyping.

Which Method Is More Cost-effective?

Urethane casting is generally more cost-effective for small runs, while injection molding requires higher upfront costs for large quantities.

Conclusion

In summary, both Injection Molding and Urethane Casting serve important roles in manufacturing. Choosing the right method depends on your project needs. If you need high volume and consistency, Injection Molding may be best. However, for low-volume and complex shapes, Urethane Casting is a great option.

Understanding the differences between these two techniques is crucial. By considering your budget, production volume, and design complexity, you can make an informed decision. Always consult with a professional, like those at Kulsa Rapid Prototype, for expert advice tailored to your project.

Now that you know the differences, you can choose the best method for your next project. Make sure to weigh your options carefully. Good luck with your manufacturing journey!

0 notes

Text

U.S. Affordable 3D Printing Solutions for Home Businesses: Market Insights and Growth Opportunities

Introduction

The rise of affordable 3D printing technology has opened new doors for entrepreneurship in the U.S., particularly for home-based businesses. With a compound annual growth rate (CAGR) of approximately 21% projected from 2024 to 2030, this market is witnessing rapid expansion and transformation. This blog post explores the various facets of the affordable 3D printing market, its significance for home businesses, challenges, and future prospects.

For more details: https://www.xinrenresearch.com/regional-reports/u-s-affordable-3d-printing-solutions-for-home-businesses-market/

1. Understanding the Affordable 3D Printing Market

1.1. Definition and Scope

Affordable 3D printing refers to the range of additive manufacturing technologies and machines that are accessible to small businesses and individual entrepreneurs. These technologies allow users to create three-dimensional objects from digital files, utilizing various materials such as plastics, metals, and even biological materials. The affordability aspect is crucial, as it enables individuals to leverage this technology without substantial financial investment.

1.2. Historical Context

3D printing technology has evolved significantly since its inception in the 1980s. Originally limited to prototyping in large corporations, advancements in technology have led to the development of cost-effective, user-friendly printers suitable for small businesses. The last decade has seen a surge in the availability of affordable models, which has fueled interest among entrepreneurs and hobbyists alike.

1.3. Market Dynamics

The affordable 3D printing market is influenced by various factors, including:

Technological Advancements: Continuous improvements in printing speed, resolution, and material diversity are making 3D printing more accessible and appealing to small businesses.

Increased Demand for Customization: Consumers increasingly seek personalized products, creating a demand for businesses that can provide tailored solutions.

Sustainability Concerns: As environmental issues become more prominent, businesses are looking for sustainable manufacturing processes, which 3D printing can offer through reduced material waste and energy consumption.

2. Advantages of 3D Printing for Home Businesses

2.1. Cost-Effective Production

Affordable 3D printing enables home businesses to produce items at a fraction of the cost of traditional manufacturing methods. By eliminating the need for expensive molds or tooling, entrepreneurs can create low-volume products economically. This cost-effectiveness is especially beneficial for startups that require flexibility in their production processes.

2.2. Rapid Prototyping

One of the significant advantages of 3D printing is the ability to quickly create prototypes. Entrepreneurs can develop and test their ideas rapidly, making modifications based on feedback before launching a product. This iterative process accelerates product development and reduces the time-to-market for new offerings.

2.3. Space Efficiency

Home-based businesses often operate within limited space constraints. 3D printers are typically compact and can fit into small work areas. This space efficiency allows entrepreneurs to manage their production processes without needing extensive facilities or equipment.

2.4. Diverse Applications

3D printing technology is versatile, enabling businesses to create various products, from functional parts and prototypes to decorative items and custom gifts. This diversity allows entrepreneurs to tap into multiple markets and cater to various customer needs.

3. Market Challenges for Home Businesses

3.1. Quality and Consistency

While affordable 3D printers offer many advantages, quality control can be a concern. Lower-end models may produce inconsistent results, leading to defects or inferior products. Entrepreneurs must invest time in learning about their machines and experimenting with different materials and settings to achieve consistent quality.

3.2. Material Limitations

Many affordable 3D printers are limited in the types of materials they can use. While plastics are the most common, entrepreneurs looking to diversify their product offerings may find these limitations restrictive. To address this challenge, businesses can seek printers that support a wider range of materials, including composites and specialty filaments.

3.3. Technical Expertise

Operating a 3D printer requires a certain level of technical expertise, from designing models to troubleshooting issues. For many entrepreneurs, this can be a steep learning curve. However, numerous online resources, tutorials, and communities are available to help users develop the necessary skills and knowledge.

4. Future Trends and Opportunities

4.1. Advancements in Technology

The affordable 3D printing market is poised for continuous growth, driven by technological advancements. Innovations such as faster printing speeds, improved material compatibility, and enhanced user interfaces will further lower barriers to entry and make 3D printing more appealing to home businesses.

4.2. Sustainable Practices

As sustainability becomes a primary concern for consumers and businesses, 3D printing is well-positioned to meet these demands. The technology allows for on-demand production, reducing waste associated with traditional manufacturing methods. Entrepreneurs can leverage this eco-friendly aspect to attract environmentally conscious customers.

4.3. Customization and Personalization

The growing trend of customization is a significant driver for the affordable 3D printing market. Businesses that can provide personalized products will stand out in a competitive landscape. As consumers increasingly seek unique items, home businesses that embrace 3D printing will have the opportunity to thrive.

4.4. Hybrid Manufacturing Approaches

Hybrid manufacturing, which combines traditional methods with 3D printing, is gaining traction. Entrepreneurs can benefit from this approach by leveraging the strengths of both technologies, enhancing their production capabilities while maintaining cost-effectiveness.

5. Key Players and Competitive Landscape

5.1. Major Manufacturers

The affordable 3D printing market is populated by various key players offering a range of printers and materials. Some notable manufacturers include:

MakerBot: Known for its user-friendly printers, MakerBot has become a popular choice among educators and hobbyists.

Prusa Research: This company is celebrated for its open-source approach, allowing users to modify and improve their printers.

Creality: With a reputation for affordability, Creality offers a range of printers catering to different user needs.

5.2. Startups and Emerging Players

The market is also witnessing the emergence of innovative startups focused on niche applications or specific materials. These companies often drive creativity and innovation, pushing the boundaries of what affordable 3D printing can achieve.

5.3. Market Positioning

As the market continues to expand, businesses must carefully consider their positioning. Identifying target audiences, understanding competitive offerings, and developing unique value propositions will be crucial for success in this evolving landscape.

6. Conclusion

The U.S. affordable 3D printing market presents significant opportunities for home businesses, with a projected CAGR of approximately 21% from 2024 to 2030. As technology continues to advance, entrepreneurs can leverage the benefits of cost-effective production, rapid prototyping, and customization to create unique products that meet the evolving demands of consumers.

While challenges such as quality control and material limitations exist, the rewards of embracing affordable 3D printing far outweigh the obstacles. By staying informed about market trends, investing in skills development, and adopting sustainable practices, home-based businesses can position themselves for long-term success in this dynamic market.

As we look to the future, the potential of affordable 3D printing to revolutionize small-scale manufacturing is undeniable. Entrepreneurs who embrace this technology will not only enhance their business prospects but also contribute to the broader narrative of innovation and sustainability in the U.S. economy.

For more reports: https://www.xinrenresearch.com/

0 notes

Text

Low Volume Manufacturing of CNC Machining

CNC machining low volume manufacturing or small batch manufacturing is the process of producing small batches using computer numerical control (CNC) machines.

Why Choose Low Volume Manufacturing? When the development of new products are in the testing stage, 1-2 samples are not enough to test, and can not meet the conditions of mold opening, or the number of products customized itself is not much, customers often choose precision CNC machining of small quantities. During new product development, small batch production can shorten the R&D and production cycle, and do FMEA to predict the risk before mass production, which is conducive to test market sales, and can also quickly adapt to changes in customer orders and market demand, to achieve inventory minimization and production system flexibility.

What Are The Advantages & Features of CNC Low Volume Manufacturing? 1.High precision Products of CNC machining low volume manufacturing with a high precision of +/-0.01mm, finish up to Ra1.6, suitable for oxidation, sandblasting, painting and powder coating, electroplating, polishing, silkscreen, laser engraving and other surface treatment. 2.High flexibility CNC small batch production is highly flexible and can respond quickly to market changes and customer needs, especially suitable for customized products and prototype development. 3.No MOQ CNC machining is flexible for the quantity, 1~1000 pieces can be processed, we have various types of CNC machining machines (3-axis, 4-axis, 5-axis, imported machines) to meet the customer's customized product needs. 4.Rich selection of materials A wide range of materials can be CNC machined, including metal and plastic materials. Commonly customized materials for small batch production are: aluminium alloy, stainless steel, titanium alloy, magnesium alloy, zinc alloy, nickel alloy, copper, steel and so on. 5.Higher production time and cost Small batch manufacturing usually involves more model changeovers and programme setups, which increases production lead time and results in lower productivity. Higher unit costs due to lower production quantities and fixed costs such as depreciation of equipment and maintenance costs that cannot be spread effectively.

Applications for CNC Low Volume Manufacturing 1.Customized products For parts or products that need to be customized, CNC small batch manufacturing allows for a quick response to customer needs. 2.Prototyping During the product development phase, CNC low volume manufacturing allows for rapid prototyping to help designers validate designs and make adjustments. 3.Small batch production For products that are not in high demand, CNC low volume manufacturing can provide flexible production methods and reduce costs. In short, small batch manufacturing is suitable for customized products, R&D trials, medical devices and other areas where uniqueness and flexibility are important.

Matters Needing Attention for CNC Low Volume Manufacturing 1.CNC machining of small batches has two main purposes, one is the product itself has a low demand for customization. The other is the small batch trial production before large-scale production, which can avoid economic losses in large-scale production due to flow design errors and product design problems. Regardless of the type of product you have, it is important to choose the right manufacturer and determine the number of units to be produced in advance before producing small batches. 2.In addition, it is equally important to pay attention to the quality of the product. Generally, these pre-produced products are not put on the market, but are mainly used as trial products to examine whether the actual production matches the design expectations. If the difference is relatively large, it is necessary to make changes to the original design or even overturn the whole design and re-plan it. Therefore, in the small batch trial production must not try to save trouble, the use of materials are best in the actual production will be used.

In summary, CNC low volume manufacturing or small batch manufacturing offers significant advantages in terms of customized products, prototyping and production of small quantities, but there are challenges in terms of cost control and production efficiency.

#design#business#autos#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#low volume manufacturing#small batch#small batch manufacturing#small batch production#low volume production#cnc processing#cnc manufacturing#cnc precision machining

1 note

·

View note

Text

Rotomolding vs. Other Plastic Manufacturing Processes: A Comparative Analysis

Plastic manufacturing encompasses a diverse array of techniques, each with its unique strengths and limitations. Rotomolding, also known as rotational molding, stands as a prominent player in this field, offering distinct advantages and disadvantages compared to other popular methods.

In this blog, we will explore the key characteristics of rotomolding and contrast them with those of injection molding, blow molding, and thermoforming, empowering you to make informed decisions for your manufacturing needs.

Rotomolding:

Rotomolding Process: Involves heating plastic resin within a rotating mold, allowing it to melt and coat the mold’s inner surface, creating hollow, seamless parts.

Advantages:

Design Flexibility: Exceptional freedom to create complex shapes, undercuts, and varying wall thicknesses.

Cost-Effectiveness: Low tooling costs make it suitable for small to medium production runs.

Large Part Production: Ideal for manufacturing large, hollow parts.

Uniform Wall Thickness: Ensures consistent wall thickness and structural integrity.

Stress-Free Parts: Produces durable and impact-resistant parts.

Disadvantages:

Cycle Time: Longer cycle times compared to some other methods, potentially impacting production speed.

Material Limitations: Works best with certain types of thermoplastics.

Surface Finish: May require secondary operations to achieve smooth finishes.

Injection Molding:

Process: Involves injecting molten plastic into a closed mold under high pressure

Advantages:

High Production Rates: Ideal for mass production with fast cycle times.

High Precision: Produces parts with excellent dimensional accuracy and intricate details.

Wide Material Selection: Compatible with a vast range of thermoplastic and thermoset materials.

Disadvantages:

High Tooling Costs: Initial investment in molds can be substantial.

Design Limitations: Complex geometries and undercuts can be challenging or costly to achieve.

Wall Thickness Limitations: Limited ability to create parts with varying wall thicknesses.

Blow Molding:

Process: Involves inflating a heated plastic tube (parison) within a mold to create hollow parts.

Advantages:

Cost-Effective for Hollow Parts: Suitable for producing bottles, containers, and other hollow shapes with relatively low tooling costs.

High Production Rates: Offers fast cycle times for mass production.

Good Surface Finish: Generally produces parts with smooth surfaces.

Disadvantages

Limited Design Flexibility: Less suitable for complex shapes or parts with intricate details.

Wall Thickness Control: Can be challenging to achieve precise wall thickness control.

Material Limitations: Primarily used with thermoplastics with good melt strength.

Thermoforming:

Process: Involves heating a plastic sheet and forming it over a mold using vacuum or pressure.

Advantages:

Low Tooling Costs: Molds are relatively inexpensive compared to injection molding.

Quick Turnaround: Suitable for prototyping and small production runs.

Large Part Production: Can produce large, thin-walled parts

Disadvantages:

Limited Design Complexity: Less suitable for parts with deep undercuts or intricate details.

Material Limitations: Primarily used with thermoplastic sheets.

Wall Thickness Variations: Can be challenging to maintain consistent wall thickness throughout the part.

Choosing the Right Process

The ideal plastic manufacturing process depends on several factors, including:

Part Design and Complexity: Consider the shape, size, and intricacy of the part.

Production Volume: Evaluate the required production quantity.

Material Requirements: Determine the specific material properties needed for the application.

Budget: Consider the tooling and production costs associated with each process.

Conclusion:

Rotomolding, injection molding, blow molding, and thermoforming each offer unique advantages and drawbacks. Understanding these distinctions empowers you to select the most suitable process for your specific manufacturing needs. By carefully weighing the factors discussed above, you can ensure optimal efficiency, cost-effectiveness, and product quality.

Remember, consulting with experienced manufacturing professionals or engineers can further aid in making informed decisions and maximizing the success of your plastic manufacturing projects.

Feel free to ask if you have any specific questions about a certain manufacturing process or scenario!

0 notes

Text

A Comparison Between Rotomolding and Injection Molding

In the world of plastic manufacturing, two commonly used processes stand out: rotomolding and injection molding. Both have their unique sets of advantages and are suited for different types of products. In this blog, we will delve into the differences between rotomolding and injection molding, exploring their processes, applications, strengths, and weaknesses.

Process Overview

Injection Molding

Injection molding is a widely used manufacturing process for producing plastic parts. It involves injecting molten plastic into a mold under high pressure. The plastic is heated to a molten state, then injected into the mold cavity, where it cools and solidifies into the desired shape. Injection molding machines, molds, and automated transportation systems are essential equipment in this process.

Rotomolding

Rotomolding, also known as rotational molding, is a thermoplastic hollow molding process. In this method, plastic powder or liquid polymer is placed in a mold and heated while the mold rotates around vertical axes. The plastic gradually melts, adheres to the mold's surface, and forms the desired shape. After cooling, the mold is opened, and the product is ejected. Rotomolding is ideal for producing large, hollow, seamless, multi-layered plastic products like water tanks, medicine boxes, and containers.

Material Differences

Injection Molding

Injection molding uses a variety of materials, including polystyrene (PS), polypropylene (PP), nylon (PA), polyoxymethylene (POM), ABS, PC, and PC+ABS alloys. These materials offer a range of properties, from high strength to excellent chemical resistance.

Rotomolding

Rotomolding primarily uses polyethylene (LDPE, LLDPE, HDPE, XLPE, mLLDPE, EVA), with small percentages of polyvinyl chloride (PVC), nylon, polypropylene, and polycarbonate. The choice of material in rotomolding is driven by the need for flexibility, durability, and cost-effectiveness.

Strengths and Weaknesses

Injection Molding

Strengths: Injection molding offers high precision, excellent surface finish, and good repeatability. It is ideal for producing small, intricate parts with tight tolerances, such as remote controls and toothbrushes.

Weaknesses: Injection molding requires expensive molds and can be costly for small production runs. It also has limitations in producing large or hollow parts.

Rotomolding

Strengths: Rotomolding excels in producing large, hollow, and seamless products with good flexibility and durability. The process is cost-effective for low to medium volumes and can accommodate complex geometries. The molds are much cheaper than injection molding.

Weaknesses: Rotomolding has lower precision compared to injection molding, and the production cycle is longer.

Applications

Injection Molding

Injection molding is widely used in the automotive, electronics, medical, and packaging industries. It is particularly suited for producing small, precise parts that require high surface quality and dimensional accuracy.

Rotomolding

Rotomolding finds applications in the production of large, hollow, and durable products such as water tanks, playground equipment, and storage containers. Its ability to produce seamless and stress-free parts makes it ideal for applications where flexibility and durability are critical.

Conclusion

Both rotomolding and injection molding have their unique strengths and are suited for different types of plastic products. Injection molding excels in precision, surface finish, and repeatability, making it ideal for small, intricate parts. Rotomolding, on the other hand, offers cost-effective production of large, hollow, and durable products.

When choosing between rotomolding and injection molding, consider the product's requirements, production volumes, and budget. Each process has its advantages, and the best choice depends on the specific needs of your project.

0 notes

Text

Sand Casting: An Age-Old Technique, Meeting Modern Demands

The sand casting process, one of the oldest metal casting techniques, has been a cornerstone of manufacturing since ancient times. Known for its versatility, affordability, and efficiency, sand casting enables industries to create a broad array of components—from small, intricate parts to large, robust industrial machinery. For companies dedicated to sand casting, the process is more than just a means to create metal components; it's a sophisticated, refined method backed by craftsmanship, innovation, and precision.

In this blog, we’ll explore what makes sand casting such a valuable manufacturing method, how it works, its advantages, and why sand casting companies remain pivotal in supplying the modern world with essential metal parts and products.

What is Sand Casting?

Sand casting is a process where a mold made of sand is used to create metal parts. The sand mold is typically reinforced with binders to give it strength, while the pattern of the part (usually made of metal, plastic, or wood) is created and then packed with sand to form a cavity. Once the pattern is removed, molten metal is poured into the cavity, left to solidify, and then broken out of the sand mold.

The sand casting process is known for its adaptability, enabling manufacturers to produce parts of different sizes, materials, and complexities. From intricate gears to large engine blocks, sand casting companies specialize in delivering quality parts at scale.

How the Sand Casting Process Works

Sand casting involves several critical steps, each of which contributes to the accuracy and quality of the final product. Here’s a breakdown of the sand casting process:

1. Pattern Making

The process begins with the creation of a pattern. This is a replica of the final product, designed with allowances to account for metal shrinkage as it cools. Patterns can be made from various materials such as wood, metal, or plastic, depending on the desired surface finish and complexity.

2. Creating the Mold

Sand is packed around the pattern to create a mold. The sand, often mixed with binders to increase stability, is compacted around the pattern to form the shape of the desired part. Once the sand mold is complete, the pattern is removed, leaving a cavity in the shape of the part to be cast.

3. Melting the Metal

The selected metal is melted in a furnace to the required temperature. Common materials used in sand casting include aluminum, brass, bronze, cast iron, and steel.

4. Pouring the Metal

Once the metal reaches the right temperature, it is poured into the sand mold. Great care is taken to ensure even pouring, as this reduces the chance of defects in the final product.

5. Cooling and Solidifying

The metal is left to cool and solidify within the sand mold. The cooling time varies depending on the size and material of the casting.

6. Breaking the Mold

After cooling, the sand mold is broken apart to reveal the cast part. This stage often involves cleaning to remove sand residues and refining the part’s surface.

7. Finishing

Post-casting processes such as machining, grinding, and polishing are carried out to achieve the required dimensions and surface finish.

Why Sand Casting? The Advantages

For many applications, sand casting offers unmatched benefits. Here’s why industries choose sand casting companies for their manufacturing needs:

1. Cost-Effectiveness

Sand casting is economical, especially for small to medium production volumes. The materials used—primarily sand and binders—are low-cost, and molds can be reused. Additionally, sand casting does not require expensive, high-tech equipment, which keeps the overall cost of production manageable.

2. Versatility

Sand casting allows manufacturers to produce parts in various sizes, shapes, and weights, from a few grams to several tons. Whether the requirement is for small, detailed components or large, complex shapes, sand casting can deliver.

3. Flexibility in Material Choice

Sand casting accommodates a wide range of metals and alloys. Aluminum, bronze, cast iron, steel, and other metals can all be used in sand casting, giving industries the flexibility to choose materials based on the requirements of strength, durability, and weight.

4. Short Lead Times

In comparison to other casting processes, sand casting can often deliver faster turnaround times. For projects requiring urgent production, sand casting companies can adjust the process efficiently, allowing rapid prototyping and production.

5. Ability to Produce Complex Geometries

With careful mold and pattern design, sand casting can produce highly detailed and complex parts. From thin-walled structures to components with complex internal cavities, sand casting companies leverage the process's flexibility to meet intricate design specifications.

Industries Relying on Sand Casting

The range of applications for sand casting is vast. Here are some key industries that rely heavily on sand casting companies to fulfill their production needs:

1. Automotive

The automotive industry is a major client for sand casting, with applications in engine blocks, transmission cases, and various other components. Sand casting is essential for manufacturing durable, high-strength parts that withstand intense wear.

2. Aerospace

Aerospace demands precision and reliability, making sand casting a valuable process for components like landing gear parts and engine housings. Sand casting offers the needed balance of strength and lightweight properties, especially for aluminum alloys.

3. Heavy Equipment and Machinery

Sand casting is ideal for large, heavy parts used in construction, mining, and agricultural equipment. The process is suitable for producing wear-resistant and high-strength components that withstand heavy-duty use.

4. Energy and Power Generation

Turbine blades, pumps, valves, and other essential components for power generation are often manufactured through sand casting. Sand casting companies can work with high-temperature alloys suited to the extreme conditions in power plants.

5. Consumer Goods and Appliances

Sand casting finds applications in producing components for home appliances, hardware, and household products. The versatility of the process allows manufacturers to produce both functional and decorative items.

Quality Control in Sand Casting

Quality control is a critical element for sand casting companies to ensure that cast parts meet the precise standards required by their customers. Here are some key methods used in quality assurance:

Dimensional Accuracy Checks: Ensuring that the cast parts match the original specifications, using gauges, calipers, and coordinate measuring machines.

Non-Destructive Testing (NDT): Techniques like ultrasonic testing, X-ray, and dye penetrant inspection identify internal or surface defects without damaging the cast parts.

Metallurgical Testing: Analyzing the material properties and ensuring that the cast metal meets the required standards for strength, hardness, and composition.

Process Monitoring: Using sensors and automated systems to monitor the casting process in real time, ensuring consistency and preventing potential defects.

The Future of Sand Casting

While sand casting remains a traditional process, modern technology is continuously refining it. Innovations like 3D printing of sand molds and automated robotic systems are streamlining the casting process, improving efficiency, and enhancing the quality of cast parts. These advancements allow sand casting companies to meet the evolving demands of industries, with greater precision, speed, and customizability than ever before.

Moreover, sustainable practices, such as recycling sand and using eco-friendly binders, are gaining importance as companies aim to reduce their environmental footprint. Sand casting companies are adopting sustainable solutions to meet the environmental standards that industries and consumers expect.

Conclusion

Sand casting companies play a crucial role in today’s manufacturing ecosystem, providing a reliable, cost-effective, and versatile solution for metal casting. The ability to produce parts with complex geometries, across a variety of industries, makes sand casting a preferred choice for manufacturers worldwide. As new technologies and sustainable practices are incorporated, the process is preserving its relevance and evolving to meet modern demands.

Sand casting continues to offer tremendous value for companies and industries looking for an economical, efficient, and adaptable metal casting solution. From automotive to aerospace, energy to consumer goods, sand casting is more than just a process—it’s an art, a science, and a trusted solution that’s here to stay.

0 notes

Text

Injection Mold Manufacturing: A Comprehensive Guide

Injection mold tooling and design are critical aspects of the manufacturing process for a wide range of products, from automotive components to consumer goods. The mold, which is essentially a hollow cavity, is used to shape the plastic material into the desired form. The design and construction of the mold directly influence the quality, efficiency, and cost-effectiveness of the production process.

Mold Base

The foundation of an injection mold is the mold base. It's typically made of hardened steel or aluminum and provides a rigid structure for the other components. The base is typically split into two halves: the A-side and the B-side.

Cavity and Core

The cavity and core are the negative and positive shapes that define the final part. The cavity is the hollow space that will be filled with the plastic, while the core forms the internal features. These components are often machined into the mold base or inserted as separate pieces.

Ejector System

Once the plastic has cooled and solidified, the ejector system is used to remove the part from the mold. This system typically consists of ejector pins or plates that are pushed into the cavity to force the part out.

Cooling System

To ensure that the plastic cools evenly and quickly, a cooling system is incorporated into the mold. This system typically involves circulating a coolant, such as water or oil, through channels within the mold base. The coolant absorbs heat from the plastic, accelerating the cooling process.

Runner and Gate System

The runner and gate system is responsible for delivering molten plastic from the injection nozzle to the cavity. The runner is a channel that carries the plastic from the nozzle to the gate, which is the point where the plastic enters the cavity.

Sprue and Runner

The sprue is the main channel that connects the injection nozzle to the runner system. The runner is a network of channels that distributes the plastic to the various cavities within the mold.

Gate

The gate is the opening through which the molten plastic flows into the cavity. There are various types of gates, such as edge gates, tunnel gates, and submarine gates, each with its own advantages and disadvantages.

Vent

Vents are small channels that allow air to escape from the mold as the plastic fills the cavity. This helps prevent air pockets and ensures a complete and even fill.

Additional Components

Depending on the specific requirements of the part, additional components may be included in the mold. These can include:

Slides:Moving elements that allow for complex part geometries.

Inserts:Pre-formed parts that are inserted into the mold before the plastic is injected.

Bushing:A metal sleeve that guides the sprue or runner.

Design Considerations

1. Part Geometry:The shape and complexity of the part will significantly impact the mold design. Features like undercuts, draft angles, and wall thicknesses must be carefully considered to ensure manufacturability.

2. Material Selection:The choice of plastic material will influence the mold design, as different materials have varying properties that require specific tooling considerations.

3. Production Volume:The anticipated production volume will determine the type of mold to be used. For high-volume production, a multi-cavity mold may be more suitable, while for low-volume production, a single-cavity mold might suffice.

4. Cycle Time: The desired cycle time, or the time it takes to produce one part, will influence the mold design. Factors like cooling efficiency and runner design can impact cycle time.

5. Cost:The cost of the mold is a significant factor to consider. The design must balance the need for quality and efficiency with the cost constraints of the project.

Design Optimization

1. Simulation:Computer-aided engineering (CAE) tools can be used to simulate the injection molding process and identify potential problems before the mold is manufactured. This can help optimize the design and reduce the risk of defects.

2. Mold Flow Analysis: This analysis can help predict the flow of molten plastic within the mold, identify potential issues like air entrapment or short shots, and optimize the runner and gate system.

3. Design for Manufacturing (DFM): By considering manufacturing constraints early in the design process, it is possible to create molds that are easier to manufacture and maintain.

Conclusion

Injection mold tooling and design are critical for the successful production of plastic parts. By carefully considering factors such as part geometry, material selection, production volume, cycle time, and cost, it is possible to design and manufacture molds that meet the desired quality, efficiency, and cost requirements.

0 notes

Text

Advantages of Custom 3D Printing Services [Infographic]

Custom 3D printing services have revolutionized manufacturing by offering flexibility, speed, and cost-efficiency. These services can greatly benefit businesses looking to create prototypes, functional parts, or even small production runs.

Here are the key advantages of using custom 3D printing services:

1. Rapid Prototyping

Custom 3D printing enables rapid prototyping, allowing businesses to create and test their designs quickly. This significantly reduces the development time, helping companies bring products to market faster.

2. Cost-Effective Production

Custom 3D printing is a cost-effective alternative to traditional manufacturing methods for low-volume production runs or complex geometries. With no need for expensive molds or tooling, companies save on setup costs, making it ideal for small batches or custom parts.

3. Design Freedom

Custom 3D printing allows for intricate and complex designs that are difficult or impossible to achieve through conventional methods. This technology supports the creation of lightweight structures and advanced geometries without compromising strength.

4. Material Versatility

With custom 3D printing services, you can choose from a wide range of materials, including plastics, metals, and resins. This variety ensures that parts meet specific performance requirements, whether it’s for strength, durability, or flexibility.

5. Reduced Waste

Since 3D printing is an additive process, just the necessary material is used. This leads to minimal waste compared to subtractive manufacturing processes like CNC machining, making custom 3D printing an environmentally friendly option.

6. On-Demand Manufacturing

Custom 3D printing services allow for on-demand production, reducing the need for large inventories. Businesses can produce parts as needed, lowering storage costs and minimizing the risk of overproduction.

7. Fast Turnaround

With the ability to produce parts quickly, custom 3D printing services provide fast turnaround times, enabling businesses to meet tight deadlines without sacrificing quality.

8. Customization and Personalization

Whether you need personalized products or one-off custom designs, 3D printing excels at offering high levels of customization. This flexibility is ideal for industries such as healthcare, where tailored solutions are crucial.

Embrace the benefits of custom 3D printing services for your next project with Shenzhen Rapid Direct Co., Ltd., from rapid prototyping to high-quality, functional parts, our team is here to help you every step of the way.

Click https://tinyurl.com/4hna5ms6 to learn more about Custom 3D Printing Services. Call now at +86 0755-85276703 or email us at [email protected]

0 notes

Text

7 Innovative Ways Custom Plastic Injection Molding Can Benefit Your Business

In the ever-evolving landscape of manufacturing, businesses are constantly on the lookout for methods to streamline production while maintaining high standards of quality and efficiency. Among the myriad options available, custom plastic injection molding stands out as a particularly versatile and cost-effective solution. As companies strive to meet unique specifications and cater to specialized markets, leveraging the capabilities of injection molding companies like Crestwood Industries can provide significant advantages. In this post, we explore seven innovative ways that custom plastic injection molding can transform your business operations, enhance product offerings, and elevate your brand's market presence.

Custom Design Flexibility

One of the most compelling benefits of custom plastic injection molding is its unparalleled flexibility in design. Businesses often require components that are tailor-made to fit specific functions or aesthetic criteria. Unlike traditional manufacturing methods which may limit creativity due to their rigid processes, mold injection companies empower you with the ability to create intricate designs without compromising on durability or performance. From complex geometries to finely detailed textures, custom plastic injection molding provides a wealth of possibilities for innovation in product development.

Enhanced Production Efficiency

Time is money in today's fast-paced business environment, and efficiency is key. Custom plastic injection molding significantly reduces production time compared to other manufacturing techniques. By creating precise molds that allow for high repeatability and minimal wastage, businesses can achieve more efficient production cycles. Whether you're producing thousands or millions of units, working with experienced injection molding companies ensures a streamlined process from design through delivery — boosting productivity and ultimately enhancing your bottom line.

Material Versatility

Another advantage offered by custom plastic injection molding lies in its compatibility with a wide range of materials. This versatility means businesses can choose from an array of plastics tailored to meet specific needs such as strength, elasticity, heat resistance, or chemical stability. Mold injection companies can guide you through selecting materials that align with industry standards while also fulfilling environmental considerations such as recyclability or biodegradability—an increasingly important factor in today’s eco-conscious market.

Cost-Effectiveness Through Scale

Custom plastic injection molding is renowned for its cost-effectiveness at scale—a crucial consideration for any business looking to maximize profit margins. Once molds are created, they can produce large quantities of parts quickly and consistently at relatively low per-unit costs compared to alternative methods like CNC machining or additive manufacturing. The upfront investment in mold creation pays dividends over time as production scales up—making it an ideal choice for businesses planning long-term projects or those seeking rapid market entry.

Improved Product Quality and Consistency

Finally, one cannot overlook how custom plastic injection molding enhances product quality and consistency—a hallmark of any reputable brand aiming for customer satisfaction and loyalty. The precision engineering inherent in mold design ensures each component meets stringent specifications time after time—which translates into reliable products right off the assembly line without defects prevalent in less controlled manufacturing environments.

Conclusion:

In conclusion, adopting custom plastic injection molding offers transformative benefits that extend beyond merely reducing costs—it opens new avenues for innovation while ensuring consistent quality across large volumes of production runs. By partnering with industry leaders like Crestwood Industries—one among many notable mold-injection companies—you gain access not only to cutting-edge technology but also invaluable expertise honed over years dedicated exclusively towards perfecting this craft within diverse sectors worldwide! Embracing these innovations allows businesses not only survive but thrive amidst modern challenges posed by competitive markets continuously demanding excellence above all else!

#injection molding companies#custom plastic manufacturer in illinois#plastic manufacturer#plastic molding services

0 notes

Text

Comprehensive Guide to Sand Casting Services

Sand casting is a popular and versatile manufacturing process that involves pouring molten metal into a mold made of sand to create complex metal parts. It is widely used in various industries due to its cost-effectiveness, ability to handle large-scale production, and flexibility in material selection. In this article, we will delve into the intricacies of sand casting services, explore the process, and understand why it is one of the most preferred methods in the manufacturing world.

Understanding Sand Casting

Sand casting, also known as sand molded casting, is one of the oldest and most widely used processes for metal casting. It is characterized by the use of sand as the mold material. This method is applicable to nearly any metal that can withstand high temperatures and is adaptable for creating both small and large parts.

The sand used in this process typically consists of silica, bonding agents, and water. The mold is created by packing sand tightly around a pattern of the desired object. Once the mold is formed, molten metal is poured into the cavity created by the pattern, where it cools and solidifies to form the final product.

Step-by-Step Sand Casting Process

Pattern Creation: The first step in the sand casting process is designing and constructing the pattern, which is a replica of the object to be cast. Patterns can be made from various materials, such as wood, metal, or plastic. The choice of material depends on the number of castings to be produced and the required precision. For instance, wooden patterns are often used for low-volume production, while metal patterns are preferred for high-volume runs due to their durability.

Mold Making: The pattern is placed in a flask, a box that holds the mold, and sand is packed around it. The sand is compacted tightly to capture every detail of the pattern. Once the mold is formed, the pattern is removed, leaving behind a cavity that mirrors the shape of the final product. The mold is made in two halves: the cope (top half) and the drag (bottom half). The two halves are aligned with the help of pins.

Core Placement (if needed): If the casting requires hollow sections, a core is placed inside the mold cavity before the molten metal is poured. Cores are made from sand and provide the necessary internal geometry for the casting.

Pouring the Metal: Once the mold and core are ready, the next step is pouring molten metal into the cavity. The metal is heated to its melting point, then carefully poured into the mold through a gating system that directs the flow. Common metals used in sand casting include aluminum, iron, steel, bronze, and magnesium alloys.

Cooling and Solidification: After the metal is poured into the mold, it needs time to cool and solidify. The cooling rate plays a significant role in determining the final properties of the cast part. Rapid cooling results in a finer grain structure, while slower cooling may cause coarser grains and potential defects.

Shakeout and Finishing: Once the metal has solidified, the sand mold is broken away in a process known as shakeout. This exposes the cast part, which is then cleaned and trimmed. Any excess metal, such as sprues and gates (channels that directed the metal flow), is removed. Additional finishing processes, such as grinding, polishing, and heat treatment, may be applied to improve the surface finish and mechanical properties of the casting.

Advantages of Sand Casting Services

1. Cost-Effective: Sand casting is one of the most cost-efficient methods for producing metal parts. The primary reason is the use of inexpensive materials, such as sand, to create the mold. Additionally, patterns can be reused multiple times, reducing overall production costs, especially for large-volume orders.

2. Versatility in Material Choice: Sand casting allows for the use of a wide variety of metals and alloys, from ferrous (steel, iron) to non-ferrous (aluminum, copper) materials. This makes it suitable for industries like automotive, aerospace, machinery, and construction, where different material properties are required.

3. Ability to Produce Complex Geometries: The flexibility of sand molds enables the creation of highly intricate and complex parts that would be difficult or impossible to produce using other casting methods. Cores allow for internal cavities and detailed geometries, making sand casting ideal for producing engine blocks, valve bodies, and intricate industrial components.

4. Scalability: Sand casting is well-suited for both low-volume and high-volume production runs. It can be used for one-off custom parts, prototyping, or mass production. The scalability of the process makes it ideal for industries with varying production needs.

5. Size Flexibility: Sand casting can accommodate a wide range of part sizes, from small precision components to massive parts weighing several tons. This versatility in part size makes sand casting a preferred method for industries such as energy, transportation, and heavy machinery.

Challenges and Limitations of Sand Casting